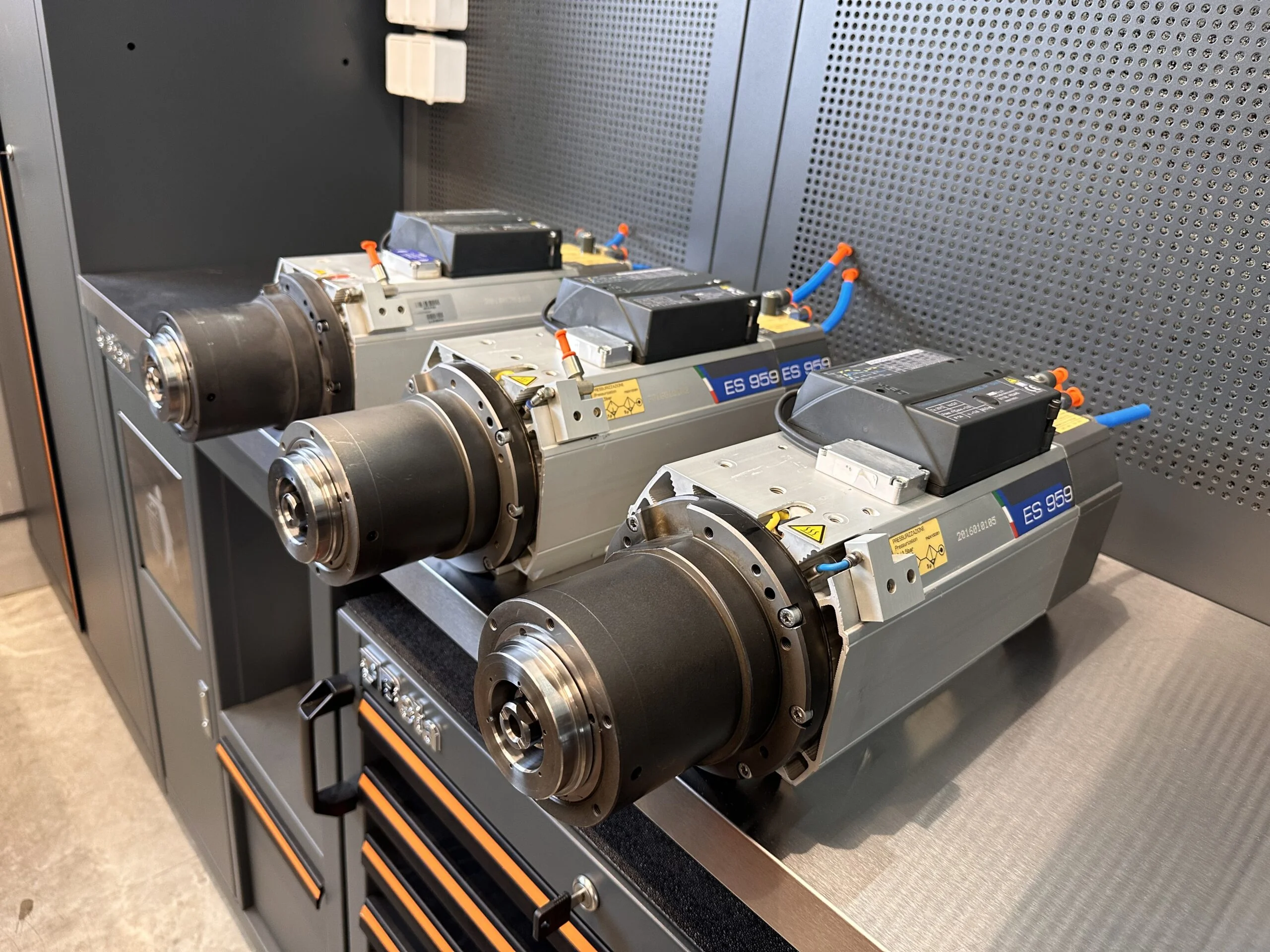

HSD spindles play a crucial role in many machines used in manufacturing and production. When these spindles face problems, machines can stop working efficiently, causing delays and losses. Hiring professional HSD spindle repair services ensures that machines get the right care and continue running smoothly.

Skilled repair technicians have the knowledge, tools, and experience to fix spindles quickly and accurately, reducing downtime and preventing further damage. Choosing experts for spindle repair saves both time and money while maintaining the quality of the machine’s performance.

Expert Knowledge and Experience

One of the main reasons to hire HSD spindle repair services is their expert knowledge and experience. These technicians understand how different spindle models work and can quickly identify problems that might be difficult for others to spot. Their training allows them to handle complex repairs without causing more issues.

Experienced professionals can also provide advice on proper maintenance to prevent future problems. Machines repaired by experts last longer and perform better because the repair is done correctly the first time.

Use of Advanced Tools and Technology

HSD spindle repair services use advanced tools and technology to diagnose and fix problems. Machines today are precise, and even a small mistake can affect performance. Professional repair services have specialized equipment to measure spindle alignment, balance, and vibration levels.

They can detect tiny issues that might be missed by standard repair methods. Using the right technology ensures that the spindle is restored to its original condition. This level of precision is difficult to achieve without professional tools and training.

Time-Saving and Efficient Service

Hiring professional spindle repair services saves significant time. Attempting to repair a spindle without experience can take days or even weeks. Experts can complete repairs quickly because they know the process and have all the necessary tools ready.

Fast repair reduces machine downtime, which keeps production schedules on track. Efficient service also prevents small problems from turning into bigger, more expensive issues. Businesses benefit when machines return to work promptly and continue producing at full capacity.

Cost-Effective Solution

Professional HSD spindle repair services provide a cost-effective solution in the long run. Trying to repair a spindle without proper skills may lead to mistakes that require more parts or even a full replacement. Paying for professional repair ensures that the spindle functions properly, avoiding repeated breakdowns.

In addition, technicians often recommend maintenance tips that extend the life of the spindle. Spending money on professional service now can save much more in repairs and replacements later.

Improved Machine Performance

Proper spindle repair directly improves machine performance. A well-repaired spindle runs smoothly, reduces vibration, and maintains accuracy in production. This ensures that finished products meet quality standards and machines operate efficiently. Professional repair services also perform testing after repair to confirm everything works correctly.

Improved performance reduces waste, enhances safety, and increases overall productivity. Machines with properly repaired spindles perform like new, providing better results for the business.

Conclusion

HSD spindle repair services offer multiple benefits for businesses that rely on machinery. Their expertise, use of advanced tools, efficient service, cost savings, and ability to improve machine performance make them an essential choice.

Hiring professional repair services ensures that machines remain in excellent condition, production continues without interruption, and long-term costs decrease. Choosing the right spindle repair experts helps maintain smooth operations and high-quality results.